Applications-By Monika Engineers

Applications

Special Purpose Machine

A Special Purpose Machine (SPM) is a custom-designed machine built to perform specific, repetitive tasks in manufacturing or assembly processes, enhancing efficiency and precision. Unlike standard machines, SPMs are tailored to meet unique production requirements, often automating complex operations that would be time-consuming or error-prone if done manually.

Bakery Machine

A Bakery Machine is a specialized piece of equipment designed to automate various baking processes, such as mixing, kneading, proofing, shaping, and baking dough. These machines streamline production in bakeries, improving consistency, speed, and efficiency, while reducing manual labor and ensuring high-quality baked goods.

Packaging Machine

A Packaging Machine is a device used to automate the process of packing products into containers, such as boxes, bags, or bottles, for distribution and sale. It handles tasks like filling, sealing, labeling, wrapping, and palletizing, enhancing efficiency, protecting products, and ensuring consistent packaging quality across various industries.

CNC Lathe

A CNC Lathe (Computer Numerical Control Lathe) is a precision machine tool used for shaping metal, wood, or plastic by rotating the workpiece against various cutting tools. Controlled by computer programs, it allows for highly accurate and complex machining operations like turning, threading, drilling, and facing, making it essential in manufacturing industries for producing detailed cylindrical parts.

CNC Grinders

CNC Grinders (Computer Numerical Control Grinders) are precision machines used for grinding and finishing surfaces to high accuracy and smoothness. Controlled by computer programs, these machines utilize abrasive wheels to remove material from metal, ceramics, or other hard substances, producing parts with tight tolerances and superior surface finishes. They are commonly used in industries like automotive, aerospace, and toolmaking for shaping and sharpening tools, dies, and other components.

CNC Milling

CNC Milling (Computer Numerical Control Milling) is a machining process that uses rotating multi-point cutting tools to remove material from a workpiece, creating precise shapes, holes, and contours. Controlled by computer programs, CNC milling machines can produce complex parts with high accuracy and repeatability, making them widely used in industries like aerospace, automotive, and manufacturing for creating intricate components from metals, plastics, and other materials.

CNC Drilling

CNC Drilling (Computer Numerical Control Drilling) is a machining process that uses a rotating drill bit to create precise holes in a workpiece, guided by computer-controlled movements. This method allows for accurate drilling of various hole sizes and patterns in metals, plastics, wood, and other materials, enhancing efficiency and consistency in mass production settings across industries like manufacturing, aerospace, and automotive.

Dying Machine

A Dyeing Machine is specialized equipment used in the textile industry to apply color to fabrics, yarns, or fibers through immersion in dye solutions. These machines ensure even and consistent color application, temperature control, and efficient dye penetration, enhancing the quality and appearance of textile products while optimizing the dyeing process for large-scale production.

Spinning Machine

A Spinning Machine is a device used in the textile industry to convert fibers, such as cotton, wool, or synthetic materials, into yarn or thread through twisting and drawing processes. These machines automate spinning, improving the speed, consistency, and quality of yarn production, which is essential for creating fabrics, garments, and other textile products.

Boiler Automation

Boiler Automation refers to the use of control systems and sensors to automatically manage and optimize the operation of boilers, ensuring efficient and safe steam or hot water production. Automated systems regulate critical parameters such as temperature, pressure, water levels, and fuel feed, reducing human intervention, enhancing energy efficiency, minimizing operational costs, and improving safety in industrial and commercial boiler operations.

Vertical Turning Lathe

A Vertical Turning Lathe (VTL) is a machine tool designed for turning large and heavy workpieces while oriented vertically. Unlike traditional horizontal lathes, the vertical orientation allows for better handling of large components, such as those used in aerospace or heavy machinery. The VTL’s design facilitates efficient cutting and machining of complex geometries and large diameters with high precision.

Power Presses

Power Presses are machines used to shape, cut, or form metal and other materials through high-pressure applications. They operate by using a mechanical or hydraulic system to drive a press tool onto the material, creating products like stamped parts, metal components, or intricate shapes. Power presses are widely used in manufacturing for their ability to handle high production volumes and deliver consistent, precise results.

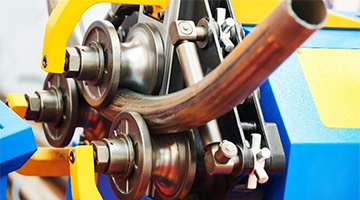

Bending Machine

A Bending Machine is used to shape metal, plastic, or other materials by applying force to bend them into desired angles or curves. These machines can handle various bending operations, such as sheet metal bending, tube bending, and pipe bending, using hydraulic, mechanical, or electric systems. Bending machines are essential in manufacturing for creating components like frames, brackets, and structural elements with accuracy and consistency.

Plazma Machine

A Plasma Machine, or plasma cutting machine, is a tool that uses a high-velocity jet of ionized gas (plasma) to cut through metal and other conductive materials with precision. The plasma is created by passing an electrical current through a gas, which then heats and ionizes the gas to form a plasma arc. This technology is widely used in manufacturing and fabrication for its ability to produce clean, accurate cuts and handle a variety of material thicknesses and types.

Lazer Cutting Machine

A Laser Cutting Machine uses a focused beam of high-energy laser light to precisely cut or engrave materials such as metal, wood, plastic, and fabric. The laser beam melts, burns, or vaporizes the material along a programmed path, allowing for intricate and accurate cuts with minimal waste. This technology is popular in industries such as manufacturing, aerospace, and design for its precision, versatility, and ability to handle complex shapes and detailed patterns.